Technology

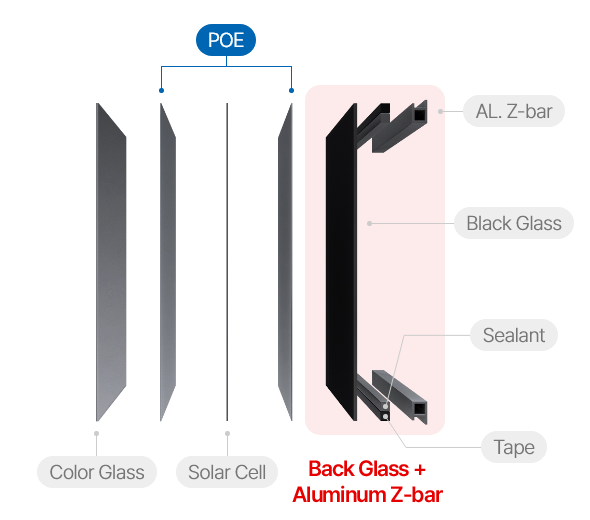

01Glass to Glass / Glass to Steel Diagram Comparison

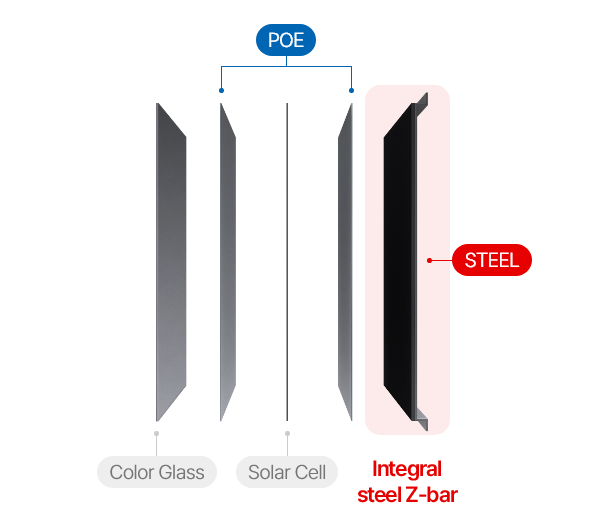

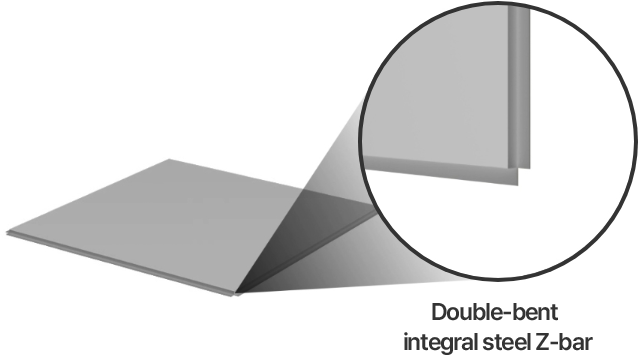

02Integral Z-bar (Glass to Steel) manufacturing technology

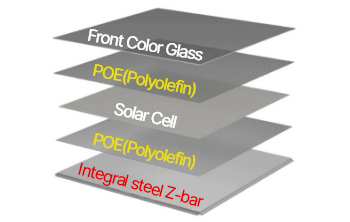

03Polyolefin (POE) Packaging Tenchology

Comparison of packaging material properties

| Item | EVA(Ethylene Vinyl Acetate) | POE(Polyolefin) | Remarks |

|---|---|---|---|

| Vinyl Acetate Content (Vinyl Acetate)(wt%) | 28±4 | 0 | |

| PID(Potential-induced degradation) Volume resistivity(Ω-Cm) | ≥1×1014 | ≥1×1016 | 100x ↑ |

| Glass adhesion strength (N/cm) | 154 | 272 | 1.7x ↑ |

| Degree of crystallinity (%) | 9.9 | 20.2 | 2x ↑ |

| Moisture penetration rate WVTR(38℃×90% RH,500um)(g/m2-day) | 34 | 3.3 | 1/10x ↓ |

Improvement

Long-term reliabilityas a building material can be ensured by utilizing POE packaging materials.

- EVA(Ethylene Vinyl Acetate)

- PID(Degradation due to electrical potential difference)

- Delamination(Occurrence of moisture penetration/Delamination/thermal expansion)

- Corrosion (acetic acid)

- POE(Polyolefin)

- Anti - PID

- Significantly lower delamination due to low moisture penetration rate

- No Corrosion

04Glass to Glass / Glass to Steel BIPV Comparison

Glass to Glass

VS

Glass to Steel

| Tempered glass + aluminum Z-bar | Rear material | Integral steel Z-bar EGI |

|---|---|---|

| Non-flammable AL melting point (660℃) |

Non-flammable properties(1200℃ in case of fire) | Super non-flammable EGI melting point (1500℃) |

| 90.5% | Thermal resistance (at 33℃ external temperature)(STC 100%) | 92.5% |

| 100% | Price | 90% (compared to G to G) |

| 46Kg | Weight(based on 1000x2000) | 37Kg (20% reduction) (compared to G to G) |